Automate the warehouse Processes

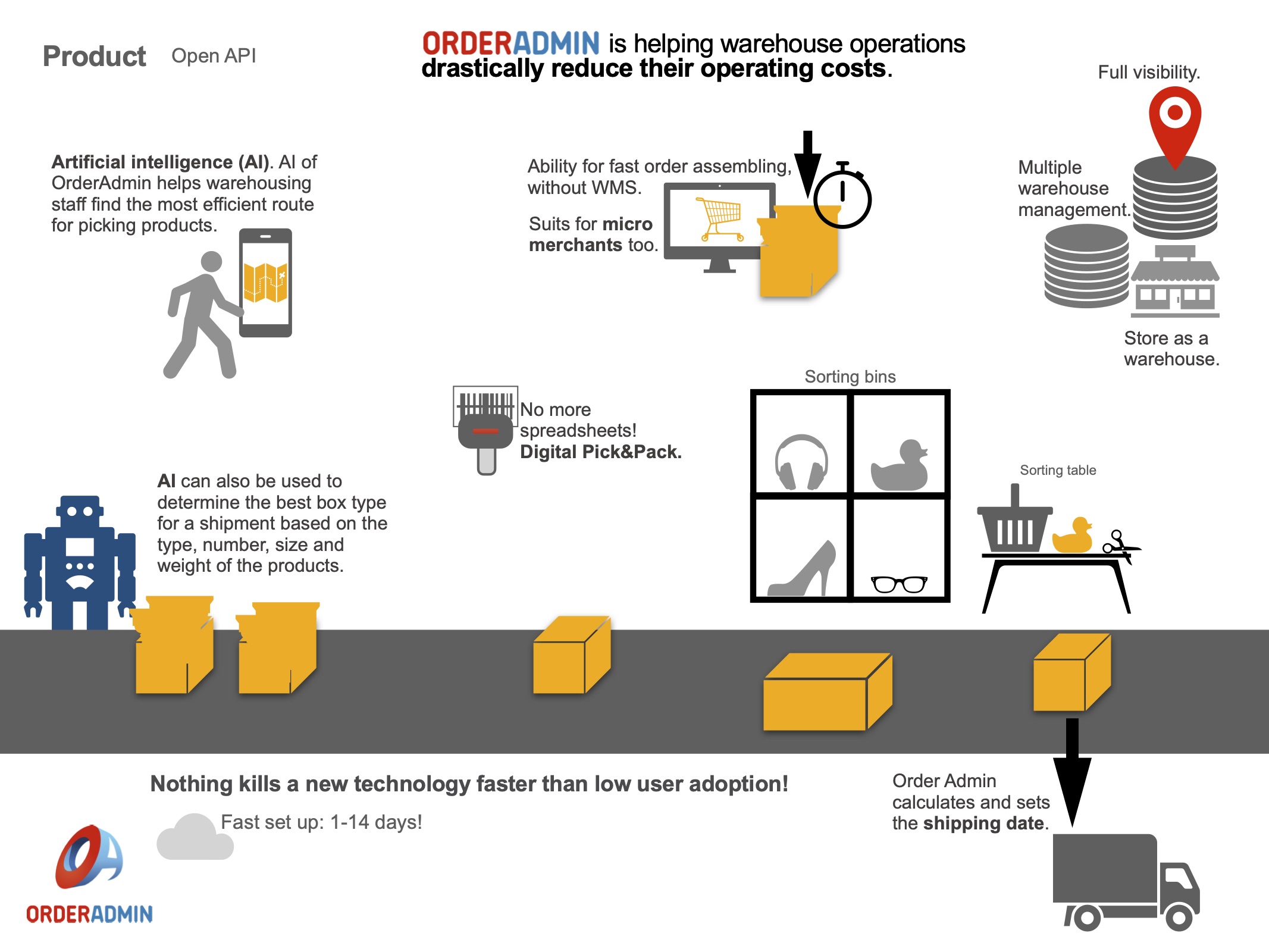

It is difficult to get more money during seasonal jumps of orders, because you need to hire more people. Moreover, it is a big challenge when all workflow processes is on papers and in multiple spreadsheets.

It is necessary for warehouse employees to have effective communication skills to facilitate the carrying out of tasks and preventing costly mistakes.

You, as warehouse manager, need to provide opportunities for employees to exchange tips for more efficient warehouse processes.

You need to train your current staff how to work smarter. You need to make a warehouse labor plan. You need to reduced staff turnover.

What if all warehouses processes can be automated?

With a WMS creating the pick list, and using tablets to scan items during the pick process, not only will employee productivity increase, labor costs will decrease.

What if you can get rid of the pick list as well and get total Digital Pick&Pack process?

Cutting your warehouse labor costs can improve the organization’s overall efficiency and increase earnings. The key is to devise ways that produce an impressive return on investment instead of simply reducing staff.

Do you know the key metrics on which you should focus for your operation to reach the maximum rate of success?

Order Accuracy % – Error-Free Orders vs Total Orders Shipped. Orders per Hour – Orders Picked&Packed vs Total Warehouse Labor Hours. Items per hour – Items Picked&Packed vs Total Warehouse Labor Hours, and more others.Using your warehouse management system you can run reports and use dashboards for easy visualisation and have access to drill down details of the key performance indicator data.

Check the metrics of our real Client case and compare with you. What would you make better in your warehouse?